Amid ecological concerns, cement industry has grown by leaps and bounds in hill state

Himani Sharma

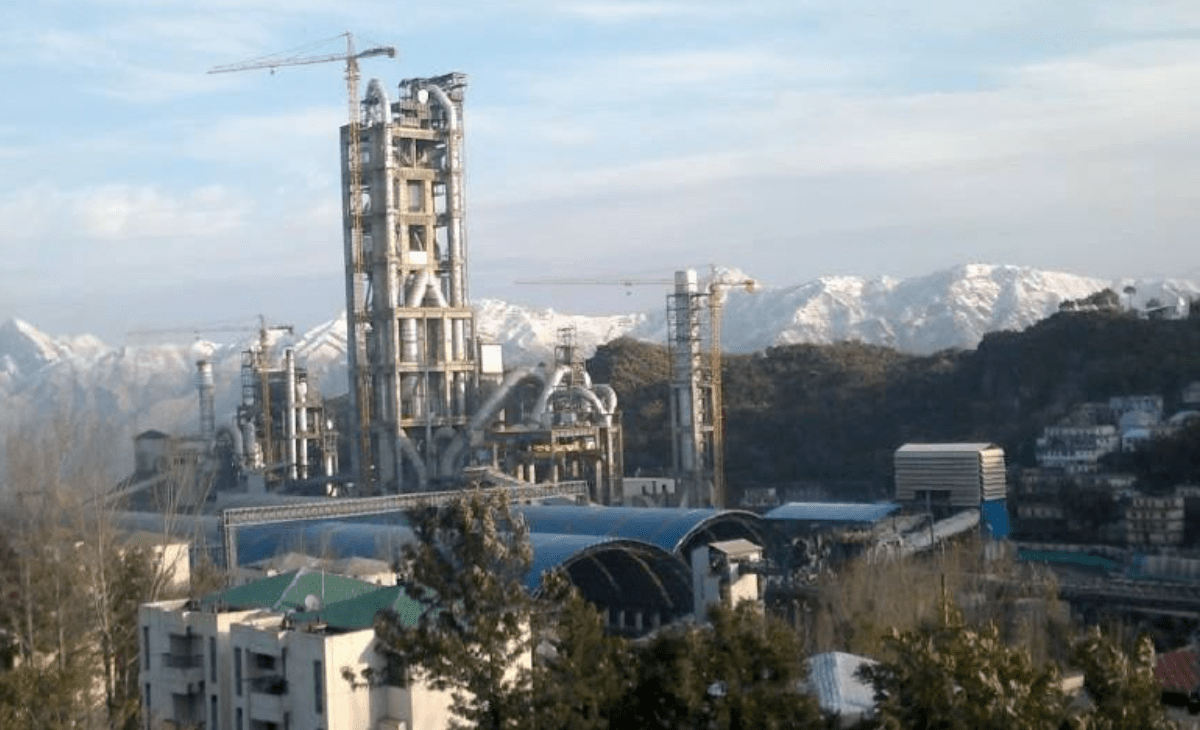

Nestled in the majestic folds of the Himalayas, Himachal Pradesh has long been known for its natural beauty with rolling hills, cedar forests and pristine rivers. Yet beneath this scenic calm lies a story of industry, ambition and environmental introspection, the story of the Himachal cement industry, one of the state’s most significant yet debated economic backbones.

The story of cement in Himachal began in the early 1960s when the Cement Corporation of India (CCI) identified the Rajban region in Sirmaur district as a site rich in high-grade limestone. The area’s mineral wealth, availability of water and road connectivity to the plains made it ideal for setting up a cement manufacturing plant.

In 1980, the Rajban Cement Factory officially began production, marking the birth of the cement industry in the state. Initially managed by the public sector, it aimed to provide affordable cement for national infrastructure projects while creating employment in the hill districts.

The plant’s success demonstrated the state’s industrial potential and encouraged private companies to explore similar ventures.

Soon after, major players such as ACC, Ambuja, Dalmia and UltraTech established plants in regions like Gagal in Bilaspur, Darlaghat in Solan, Rauri in Mandi and Nalagarh in Solan. The once quiet valleys began to resonate with the hum of modern industry as Himachal emerged as a key cement producer in North India.

With growing markets in Punjab, Haryana, Delhi and Jammu and Kashmir, the state’s plants became vital suppliers for the northern construction boom. The industry generated thousands of jobs and contributed significantly to the state’s economy and infrastructure development.

Price of progress

But progress, as history often reminds us, comes at a price. Large-scale limestone mining and heavy industrial activity have left a visible mark on the fragile Himalayan ecosystem. Mining has altered landscapes, created dust pollution and affected local water sources.

Villagers near quarry zones have reported reduced agricultural yield and groundwater depletion. The transportation of raw materials through narrow mountain roads has also led to traffic congestion and road damage in certain regions.

Rising fuel and energy costs further challenge production, while stricter environmental regulations often delaying expansions or new projects. Balancing economic benefit with ecological responsibility remains one of the industry’s biggest tests.

As awareness grows, community voices are becoming louder. “Factories have given us jobs but also taken away our peace and clean air,” says a resident from Darlaghat. “There needs to be a balance.”

Adapting to changing world

In recent years, Himachal’s cement producers have started adopting cleaner and more efficient practices. Many have introduced co-processing, where industrial and municipal waste is used as alternative fuel, reducing both fossil fuel consumption and waste disposal problems.

The industry is shifting toward blended cements that use fly ash and slag to lower carbon emissions. Plants are installing waste heat recovery systems to generate electricity from excess heat released during production. These initiatives not only improve efficiency but also align with India’s broader goals of sustainable industrial growth.

The Himachal government is promoting green manufacturing and stricter environmental monitoring to ensure that industrial progress does not come at the cost of natural heritage.

Rehabilitation of mined areas and community participation programs are slowly becoming part of the policy framework.

Balancing economy and ecology

The demand for cement is expected to rise as India continues to build roads, tunnels, hydroelectric dams and housing projects. Himachal, with its strategic location and quality limestone, will continue to play a key role.

However, experts believe that the future depends on innovation and accountability. Investment in low carbon technologies, carbon capture research and digital monitoring can make operations cleaner and more sustainable. Greater transparency in land use and fair compensation for affected communities will also strengthen trust and cooperation.

The Himachal cement industry stands at a turning point between industrial legacy and environmental responsibility. The decisions taken now will shape whether it remains just another extractive industry or becomes a model of sustainable development in the Himalayas.

In the end, the cement that holds together Himachal’s future must not only build roads and bridges but also bind together progress and preservation.

Himani Sharma